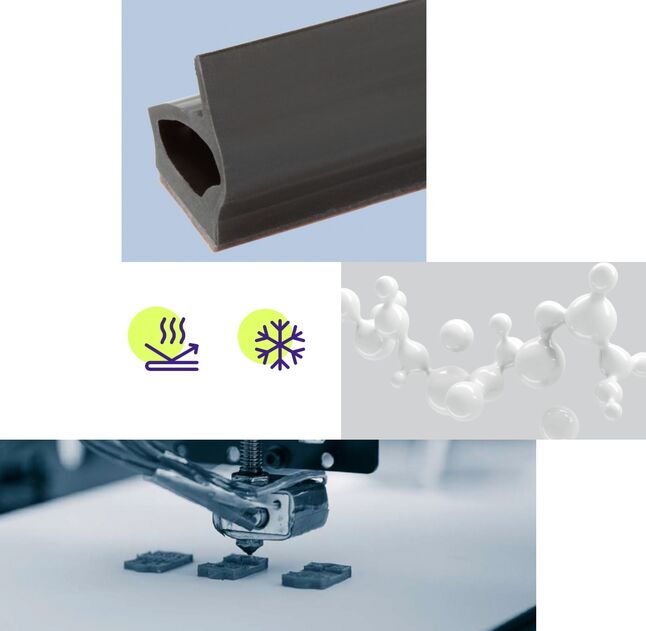

Our competenciesCustomized

silicone

solutions

Silnova combines extrusion and injection moulding for efficient and targeted development through to the sale of customer-specific hoses, sealing and fittings made of silicone. With our German quality standard and our worldwide network, we offer you custom-fit silicone solutions.

Application areasCross-industry use

We develop innovative and individual solutions, precisely customized for your application and guide our customers from the conceptualization to the assembly.

Let’s synergize!

Get in touch

We have the silicone solution for your application.

Please fill in the fields marked with an *.